The Ultimate Guide to metal jig saw blades: Everything You Need to Know

When it comes to cutting through metal with precision and ease, a high-quality metal jig saw blade is an essential tool for any DIY enthusiast or professional. Whether you are working on a small home improvement project or tackling a larger industrial job, choosing the right blade can make all the difference. In this comprehensive guide, we will explore the various aspects of metal jig saw blades, including their types, materials, features, and applications. By the end of this article, you will have a solid understanding of metal jig saw blades and be able to select the perfect blade for your next project.

1. Understanding Metal Jig Saw Blades

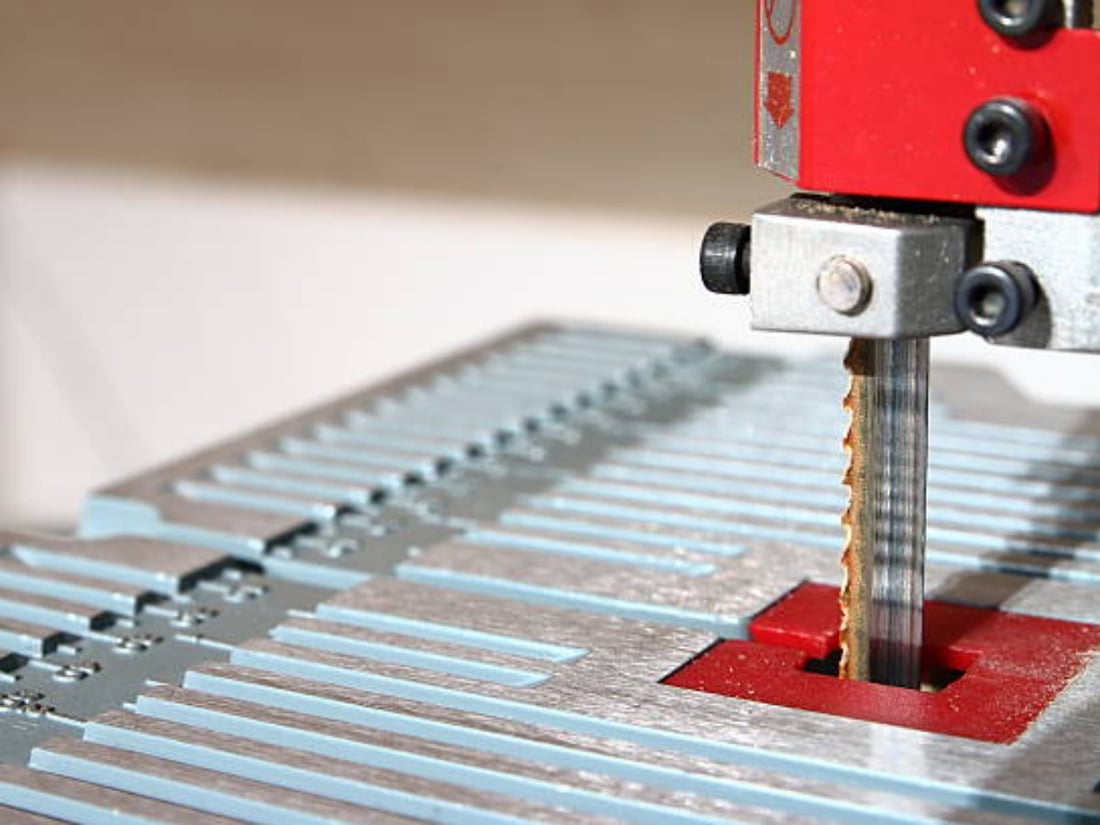

Metal jig saw blades are specifically designed to cut through various types of metal, including steel, aluminum, and copper. These blades feature a unique tooth design that allows for efficient and precise cutting. Unlike the traditional reciprocating saw blades, jig saw blades have smaller, finer teeth that enable more intricate and detailed cuts. They are commonly used for cutting curves, circles, and other irregular shapes in metal materials.

2. Types of Metal Jig Saw Blades

There are several types of metal jig saw blades available on the market, each designed for specific applications. The most common types include:

2.1 High-Speed Steel (HSS) Blades

HSS blades are the most versatile and widely used metal jig saw blades. They are made from a combination of steel and various other materials, such as cobalt, to enhance their durability and cutting performance. HSS blades are suitable for cutting both thin and thick metals and offer a good balance between cost and performance.

2.2 Bi-Metal Blades

Bi-metal blades are constructed from two different types of metal, typically high-speed steel and high-carbon steel. This combination creates a blade that is incredibly durable and can withstand high heat and pressure. Bi-metal blades are recommended for heavy-duty cutting tasks and can easily cut through thick metal materials.

2.3 Carbide-Tipped Blades

Carbide-tipped blades are specifically designed for cutting through hard and abrasive metals, such as stainless steel or cast iron. These blades feature small carbide teeth that are incredibly sharp and long-lasting. While carbide-tipped blades may be more expensive, they offer exceptional cutting performance and extended blade life.

2.4 Diamond-Grit Blades

Diamond-grit blades are ideal for cutting through extremely hard materials, such as tile, stone, or glass-infused metals. These blades have diamond particles embedded in their cutting edge, providing superior cutting power and durability. Diamond-grit blades are not suitable for general metal cutting, but they excel in specialized applications.

3. Factors to Consider When Choosing a Metal Jig Saw Blade

Choosing the right metal jig saw blade for your project requires careful consideration of several factors. Here are some key factors to keep in mind:

3.1 Material Thickness

The thickness of the metal you are cutting will determine the type of blade you should use. For thin metals, a fine-toothed blade will provide smoother cuts, while thicker metals require blades with larger teeth and more aggressive cutting action.

3.2 Blade Length

The length of the blade determines the depth of the cut. Longer blades are suitable for cutting thicker materials, while shorter blades are ideal for intricate and detailed cuts.

3.3 Teeth Per Inch (TPI)

The number of teeth per inch, also known as TPI, affects the cutting speed and finish. Higher TPI blades provide smoother cuts but may have slower cutting speeds, while lower TPI blades have faster cutting speeds but may leave a rougher finish.

3.4 Shank Type

There are two common shank types for metal jig saw blades: T-shank and U-shank. T-shank blades are the most common and widely compatible, while U-shank blades are typically used with older or less common jig saw models. Ensure that the blade you choose matches your jig saw's shank type.

3.5 Cutting Speed

Consider the cutting speed required for your project. Different blades have varying cutting speeds, so choose a blade that can handle the speed demanded by your application.

4. Tips for Using Metal Jig Saw Blades

To achieve the best results with your metal jig saw blade, follow these helpful tips:

4.1 Use Lubrication

When cutting through metal, applying a lubricant can help reduce friction and heat buildup, resulting in smoother cuts and prolonging blade life.

4.2 Start with Pilot Holes

If you are cutting through thick metal, it is advisable to start with pilot holes. These small holes act as a guide for the blade, reducing the risk of wandering and improving cutting accuracy.

4.3 Take Your Time

When cutting intricate shapes or curves, it is important to take your time and maintain a steady pace. Rushing the process can lead to mistakes and may damage both the material and the blade.

4.4 Secure the Material

Ensure that the metal you are cutting is securely clamped or held in place. This will prevent vibrations and movement, resulting in cleaner, more precise cuts.

4.5 Wear Protective Gear

Always wear appropriate safety gear, including safety glasses, gloves, and ear protection, when using a jig saw with a metal blade. Metal cutting can produce sparks and sharp edges, so protection is crucial.

5. Applications of Metal Jig Saw Blades

Metal jig saw blades find applications in a wide range of industries and projects, including:

5.1 HVAC Installations

From cutting metal ductwork to shaping ventilation openings, metal jig saw blades are essential for HVAC installations.

5.2 Automotive Repairs

When working on automotive repairs or modifications, metal jig saw blades can be used to cut and shape metal components.

5.3 Metal Fabrication

In the field of metal fabrication, jig saw blades are used for cutting intricate shapes and patterns in metal sheets and plates.

5.4 Plumbing Projects

Plumbers often use metal jig saw blades to cut through metal pipes and fittings during plumbing installations or repairs.

5.5 DIY Metalworking

For DIY enthusiasts, metal jig saw blades are indispensable for various metalworking projects, such as crafting custom metal furniture or sculptures.

6. Maintaining Metal Jig Saw Blades

Proper maintenance of your metal jig saw blades is essential to ensure their longevity and cutting performance. Here are some maintenance tips:

6.1 Clean After Use

After each use, clean the blade thoroughly to remove any metal chips, dirt, or debris. This will prevent buildup and maintain optimal cutting performance.

6.2 Store Properly

Store your metal jig saw blades in a clean and dry location, away from moisture and humidity. Consider using blade protectors or cases to prevent accidental damage.

6.3 Sharpen or Replace

If you notice a decline in cutting performance or dullness, consider sharpening the blade or replacing it with a new one. Dull blades can cause rough cuts and increase the risk of accidents.

6.4 Inspect for Damage

Regularly inspect your metal jig saw blades for any signs of damage, such as missing teeth or cracks. Damaged blades should be replaced immediately to ensure safe and efficient cutting.

7. Conclusion

Metal jig saw blades are versatile tools that can handle a wide range of metal cutting tasks, from simple DIY projects to complex industrial applications. By understanding the different types, selecting the right blade for your needs, and following proper maintenance practices, you can achieve precise and efficient cuts every time. Remember, safety should always be a priority when working with metal jig saw blades, so wear appropriate protective gear and follow the manufacturer's instructions. With the knowledge gained from this guide, you are now ready to take on your next metal cutting project with confidence!

If you are interested in our products or services, please feel free to contact us.