Introduction

When it comes to woodworking and other DIY projects, having the right tools is essential for achieving professional results. One such tool that every woodworker should have in their arsenal is a jig saw. However, the performance of a jig saw heavily relies on the quality of its blades. In this comprehensive guide, we will explore the various aspects of jig saw blades and help you find the best ones for your needs.

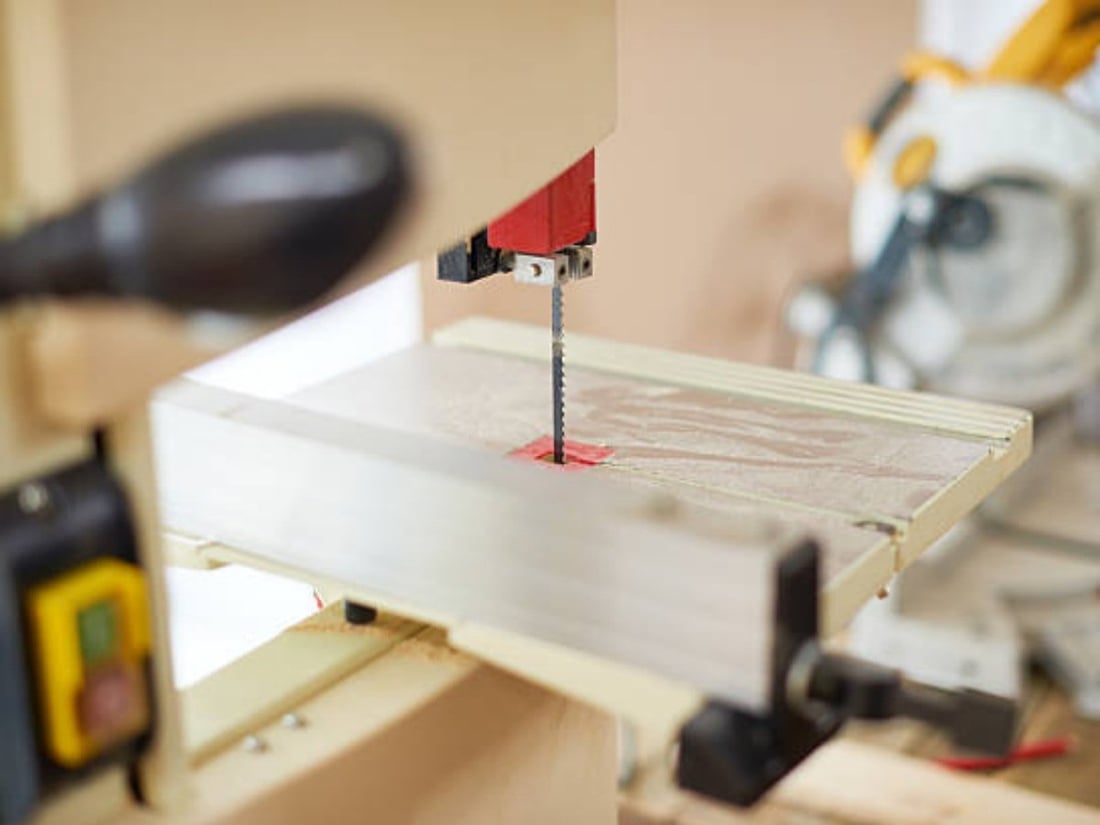

Understanding Jig Saw Blades

Before delving into the selection process, it is important to understand the anatomy of jig saw blades. Jig saw blades are typically made of high-carbon steel, bi-metal, or carbide. They consist of teeth that vary in size, shape, and arrangement. The teeth are responsible for cutting through different materials, and their configuration determines the type of cut the blade can produce. Now, let's explore the different factors to consider when choosing the best jig saw blades for your projects.

Choosing the Right Blade Material

The material used in the construction of jig saw blades plays a crucial role in determining their durability and cutting performance. There are three primary materials to choose from: high-carbon steel, bi-metal, and carbide. High-carbon steel blades are the most affordable option and are suitable for cutting softwoods and non-ferrous metals. Bi-metal blades, on the other hand, offer enhanced durability and are ideal for cutting through hardwoods and metals. Carbide blades, often the most expensive, are specifically designed for cutting abrasive materials like ceramics, fiberglass, and composites.

Selecting the Right Blade TPI

One of the most important considerations when choosing jig saw blades is the teeth per inch (TPI). The TPI determines the speed and finish of the cut. Blades with a higher TPI produce smoother cuts, while those with a lower TPI are better suited for rough cuts. For general-purpose woodworking, a blade with 10-12 TPI is recommended. However, for cutting thicker materials, a lower TPI of 6-8 would be more appropriate, while a higher TPI of 14-20 is ideal for finer cuts.

Identifying the Right Blade Shank

Another crucial aspect to consider when selecting jig saw blades is the shank type. There are two common types: T-shank and U-shank. T-shank blades have a tang that fits securely into the tool's blade clamp, offering better stability and ease of use. U-shank blades, on the other hand, have a slightly curved end that requires a set screw for attachment. T-shank blades are more widely available and compatible with most jig saw models, making them a popular choice among woodworkers.

Understanding Blade Tooth Configurations

The tooth configuration of a jig saw blade determines the type of cut it can produce. There are three common tooth configurations: wavy, reverse, and progressive. Wavy blades have teeth that alternate between facing forward and backward, resulting in aggressive and fast cuts with rough finishes. Reverse blades, as the name suggests, have teeth that face backward, allowing for smoother cuts. Progressive blades have teeth of varying sizes and tooth spacing, enabling them to cut through both thick and thin materials with ease.

Considering Blade Length

The length of a jig saw blade is an important factor to consider, as it determines the maximum depth of cut the blade can achieve. Longer blades are suitable for making deeper cuts, while shorter blades are better for intricate and detailed cuts. It is essential to choose a blade length that matches the thickness of the material you will be cutting. Using a blade that is too long may result in poor control and increased risk of breakage.

Exploring Specialized Blade Types

In addition to the standard jig saw blades, there are also specialized blade types available for specific applications. For example, scroll-cutting blades are designed for intricate and detailed cuts, making them ideal for creating decorative patterns. Metal-cutting blades have fine teeth and are specifically designed for cutting through various metals. Laminate blades feature a downward-pointing tooth that minimizes chipping when cutting laminates and veneers. Assess your specific project needs to determine if any specialized blade types would be beneficial.

Considering Blade Brand and Quality

When it comes to jig saw blades, the brand and quality of the blade can greatly impact its performance and longevity. It is recommended to opt for blades from reputable manufacturers known for their commitment to quality. Brands such as Bosch, Dewalt, and Milwaukee have earned the trust of many woodworkers and offer a wide range of high-quality jig saw blades.

Understanding Blade Maintenance and Longevity

To ensure the longevity and optimal performance of your jig saw blades, proper maintenance is essential. Here are a few tips to keep in mind:

- Regularly clean the blades to remove any debris or pitch buildup.

- Store the blades in a dry and moisture-free environment.

- Avoid excessive heat or prolonged exposure to sunlight, as it can cause blade warping.

- Use the appropriate blade for each material to prevent premature dulling or damage.

Conclusion

Investing in the best jig saw blades is a wise decision for any woodworker or DIY enthusiast. By considering factors such as blade material, TPI, shank type, tooth configuration, and length, you can ensure that you have the right blade for every project. Additionally, choosing blades from reputable brands and properly maintaining them will enhance their longevity and cutting performance. So, equip yourself with the best jig saw blades and unlock the full potential of your jig saw.

If you are interested in our products or services, please feel free to contact us.