Introduction

A Long-lasting carbide saw blade is an essential tool for anyone involved in woodworking or construction. This type of saw blade is made from carbide, a durable and high-performance material that can withstand the rigors of heavy-duty cutting tasks. In this article, we will explore the various benefits of using a long-lasting carbide saw blade, including its longevity, precision, versatility, and cost-effectiveness.

1. Longevity

One of the primary advantages of a long-lasting carbide saw blade is its longevity. Unlike traditional saw blades that wear out quickly and require frequent replacements, carbide saw blades are designed to last much longer. The carbide tips on these blades are extremely hard and can withstand the abrasiveness of cutting through various materials without losing their sharpness. This longevity translates into significant cost savings, as you won't need to replace the blade as often.

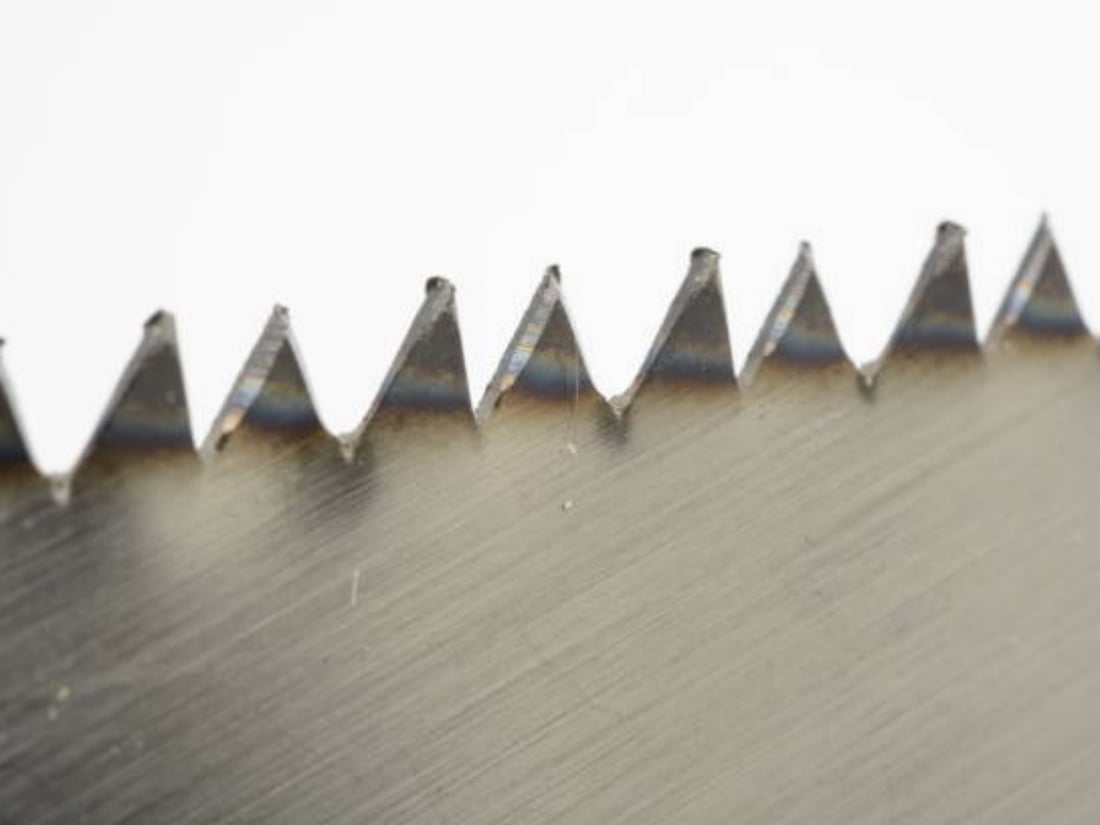

2. Precision of a Long-lasting Carbide Saw Blade

When it comes to cutting accuracy, a long-lasting carbide saw blade excels. The sharp and durable carbide teeth on these blades ensure clean and precise cuts, regardless of the material being cut. Whether you are working with hardwood, softwood, plywood, or even non-ferrous metals, a carbide saw blade will deliver smooth and accurate cuts every time. This precision is crucial for achieving professional-grade results in woodworking and construction projects.

3. Versatility

Another remarkable aspect of a long-lasting carbide saw blade is its versatility. These blades are designed to handle a wide range of cutting tasks, making them suitable for various applications. Whether you need to rip, crosscut, or make bevel cuts, a carbide saw blade can handle it all. Additionally, some carbide saw blades are designed for specific materials, such as laminate or melamine, further expanding their versatility.

4. Cost-effectiveness

Investing in a long-lasting carbide saw blade is a cost-effective choice in the long run. Though these blades may have a higher upfront cost compared to traditional saw blades, their extended lifespan and durability more than make up for it. By reducing the frequency of blade replacements, you save money over time. Additionally, the precision and efficiency of a carbide saw blade contribute to less material wastage, further enhancing its cost-effectiveness.

5. Reduced Downtime

When using a long-lasting carbide saw blade, you can expect reduced downtime due to blade changes. Traditional saw blades often require frequent replacements during a project, leading to interruptions and delays. However, with a carbide saw blade, you can work for longer periods without interruptions, maximizing productivity and efficiency.

6. Compatibility of a Long-lasting Carbide Saw Blade

Long-lasting carbide saw blades are compatible with a wide range of saws, including table saws, miter saws, circular saws, and radial arm saws. This compatibility ensures that you can use the same high-quality blade across multiple tools, saving you money and reducing the need for specialized blades for each saw. Additionally, these blades are available in various sizes and configurations to suit different saw models and cutting requirements.

7. Heat Resistance

Carbide saw blades are known for their exceptional heat resistance. This characteristic is especially beneficial when cutting through dense or hard materials that generate a significant amount of heat during the cutting process. The heat resistance of carbide blades helps prevent blade warping or dulling, ensuring consistent performance and longevity.

8. Safety

Using a long-lasting carbide saw blade also enhances safety in the workshop or job site. The sharpness and precision of these blades reduce the likelihood of kickbacks or other accidents that can occur when using dull or inefficient blades. Additionally, the durability of carbide blades minimizes the chances of blade breakage, further reducing the risk of injury.

9. Environmental Friendliness

Choosing a long-lasting carbide saw blade contributes to environmental friendliness. By reducing the frequency of blade replacements, you minimize the amount of waste generated. Additionally, many carbide saw blades are recyclable, allowing you to dispose of them responsibly at the end of their lifespan.

10. Maintenance

Finally, maintaining a long-lasting carbide saw blade is relatively simple. Regular cleaning, lubrication, and proper storage can help extend the lifespan of the blade even further. Additionally, periodic sharpening or re-tipping of the carbide teeth ensures optimal cutting performance over time.

If you are interested in our products or services, please feel free to contact us.