Guidelines for Safe Operation of a curved saw

Importance of Adhering to Curved Saw Procedures

When using a curved saw, it is crucial to follow all operational guidelines strictly. Understanding the operating principles and leveraging the curved saw’s various functions can significantly enhance productivity.

Considerations for Cutting Thin Boards with Curved Saw

It is important to note that curly saws are intended for cutting materials with sufficient thickness. Specifically, curved saws are not optimal for cutting wood boards thinner than 3mm or iron sheets below 0.3mm. Thin materials fail to provide the necessary rigidity for the high-speed vertical action of the curved saw blade. For thinner materials, consider stacking them together to achieve better support.

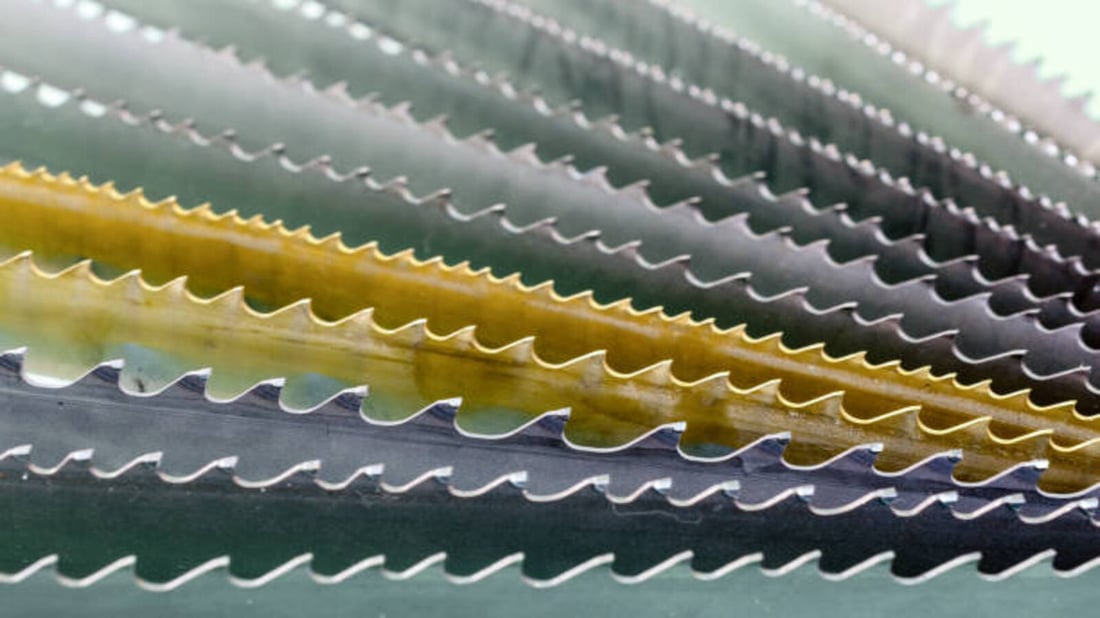

Choosing the Right Saw Blade for Your Curved Saw

Selecting the appropriate saw blade is vital for maximizing the efficiency of your curved saw. Curved saw blades come in five standard styles, primarily differentiated by their clamping mechanism. Always ensure the blade is securely tightened before operation. Curved saw blades vary in specifications, including material, thickness, surface roughness, and cutting efficiency. Make sure to select the correct blade suited to the material you are cutting; wood, aluminum, and steel all require different curved saw blade specifications. Remember to disconnect the power before changing any curved saw blade.

Conclusion

Curved saws bring extensive convenience to production operations when operated correctly. Observing safe practices and using the curved saw efficiently can lead to outstanding results.